News

Blog

About the future of product creation

Read more about

Model-Based Definition: Take Your Engineering Processes to the 21st Century

Read more about

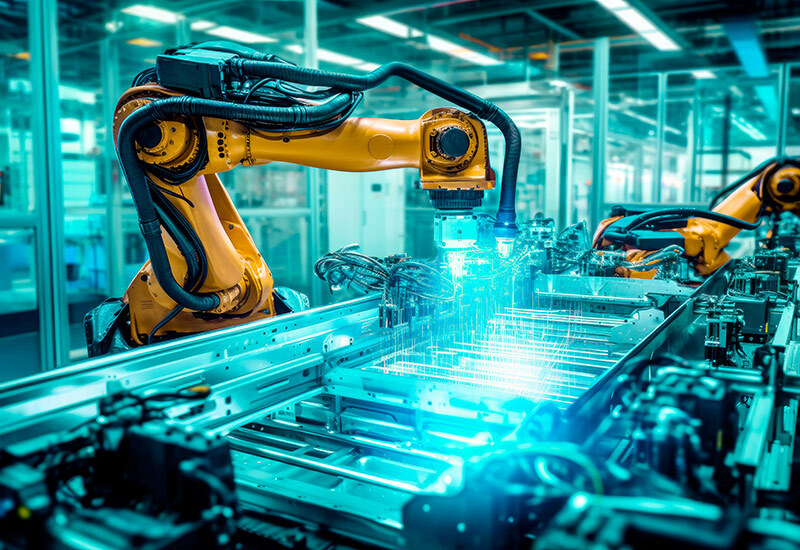

Automated Offline Programming: The Future of Robotic Manufacturing

Read more about

Implementing Simulation-Driven Design: Five Tips for a successful Start

Read more about

PLM system integration for greater market success in mechanical engineering

Read more about

How can you achieve end-to-end SAP and 3DEXPERIENCE processes?

Read more about

Offline programming with the aid of a simulation tool

Read more about

Unleashing Business Success with Smart Application Management

Read more about

Leveraging data and transparency to reduce cost risks in engineering change management

Read more about

Six trends in Digital Product Development

Read more about

Design, modeling and simulation: A unified entity that needs differences

Read more about

How to leverage sustainability to make your business more innovative

Read more about

Transforming Product Creation

Read more about

How to optimize your operational excellence by working on ASPICE

Read more about

Data continuity in manufacturing industry: How software and IT are changing

Read more about

Digital Collaboration

Read more about

How will digitalization change collaboration in your manufacturing company?

Read more about

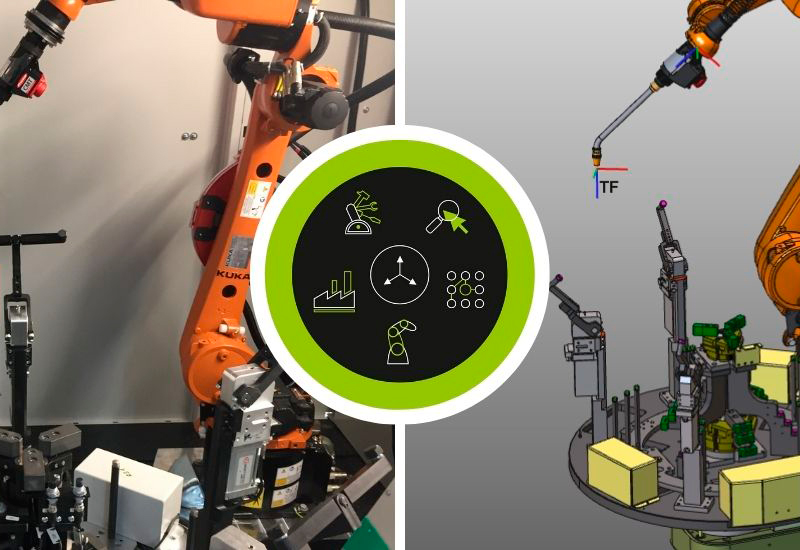

Digital Twins: Robot optimization in a matter of hours

Read more about

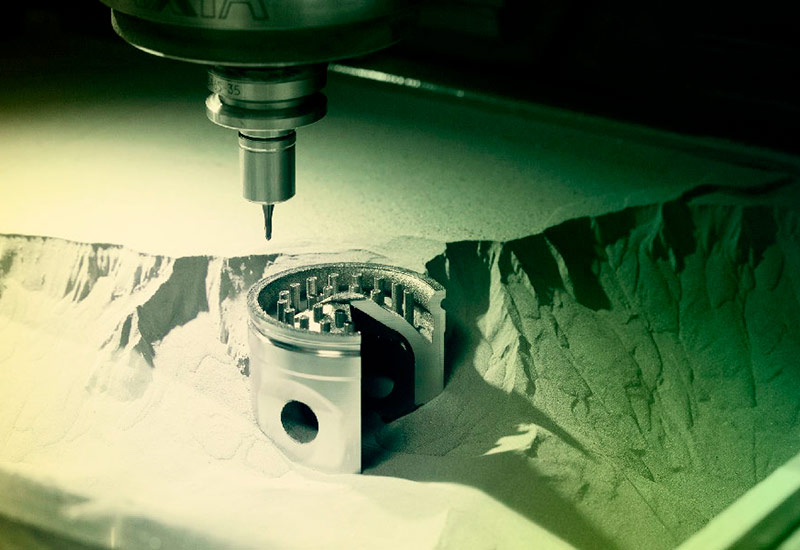

Hybrid Manufacturing

Read more about

You want to introduce PLM? Limited internal resources should not be an obstacle!

Read more about

Digital Production: Data Continuity from Design to Manufacturing

Read more about

Meissner relies more on robots

Read more about

CAD data management

Read more about

Geometric Product Specifications: Standards enable digital continuity and raise efficiency

Read more about

Leveraging SAP EPD Engineering to integrate requirements management and system modeling into your PLM process

Read more about

SaarGummi Automotive: A Smart IT Concept for Global Product Design

Read more about

Listening Improves Artificial Intelligence!

Read more about

What digital platform does my business need?

Read more about

Home Office for Robot Operators?

Read more about

Tolerance Analysis: From Excel to Digital Quality Twin

Read more about

The Digital Twin: It’s all about the Context

Read more about

Tolerance management: Digital twin reduces product lifecycle costs