Where real production becomes virtual

Software for Efficient Robotics in Production

Precision in manufacturing simplified

FASTSUITE® Edition 2 adapts to a wide range of industries through its dedicated business modules. The software provides specific solutions to meet diverse industrial needs, making it an essential tool for optimizing various processes within a factory.

FASTSUITE® Overview

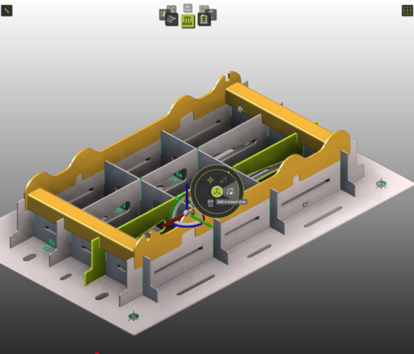

A platform that brings together robots, machines, and processes in a virtual environment

What is Offline Programming?

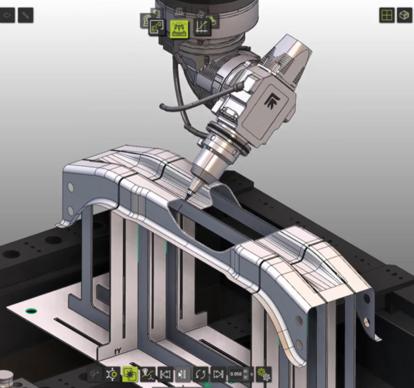

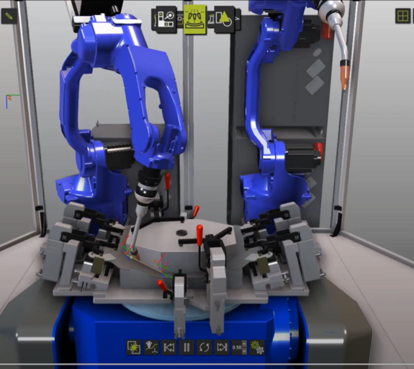

Offline programming consists of creating robot programs from CAD models then simulating these programs in the 3D digital twin of the workcell. The simulation also validates the quality, then the program can be downloaded directly to the physical workcell and used immediately for production.

What are the advantages of OLP software?

- Cost Reduction

- 50% Productivity Gain

- 25% Less Downtime

- Increased Flexibility

- Automatic Programming

- And Many More Advantages

Key Features of FASTSUITE Edition 2

The connection point between simulation and reality

Modern user interface

Graphical visualization of the process (process model)

Automatic template generation

Duplication and management of part variants

Compatibility with various CAD formats (CREO, autodesk, solidworks, catia...)

Download and Upload

Automatic trajectory generation

Synchronization of external axes

Instant fixture building under CAD parts

Thanks to its advanced 3D simulation and intuitive interface, it ensures smooth synchronization between the virtual and real worlds while seamlessly integrating with existing processes.

In the drive to modernize and optimize production resources, Offline Programming (OLP) software plays a strategic role. It perfectly adapts to your needs, allowing you to rethink processes innovatively and efficiently.

Industries

- Automotive

- Aerospace

- Heavy machinery

- Defense

- Job-shops

- Industrial equipment

- Energy

Production technologies

- Welding

- Laser cutting

- Finishing

- Non-destructive testing

- Automotive body-in-white

- Aerospace fabrication

What is the Return on Investment (ROI)?

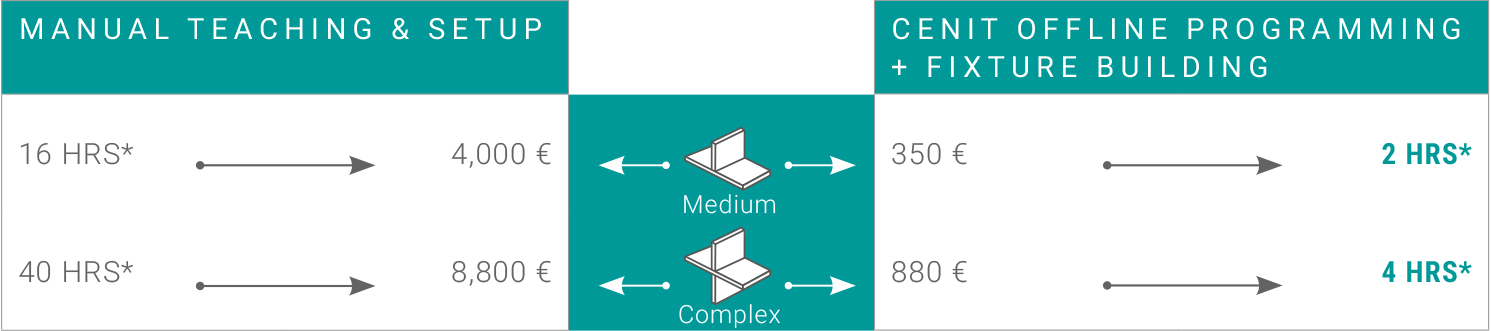

Case Study: Setting up Robotic Welding jobs (Creating programs and building fixtures)

The introduction of offline programming assumes an investment of approximately 50,800 euros. This amount consists of around EUR 33,600 in fixed costs (calibration of a cell with a robot, software implementation, training of two members of staff) and EUR 17,200 in variable costs (annual software maintenance). Calculation of the ROI refers to the production of 10 parts of medium complexity and 5 parts of high complexity per year.

Fetzer Contact me now