Cloud-based offline programming for flexible robotics

FASTCUBE

Automation that adapts to your reality

FASTCUBE brings offline programming to a modular cloud platform – scalable and designed specifically for the shop floor. From CAD and simulation to manufacturing, FASTCUBE creates a continuous digital workflow without downtime or media breaks. Developed for SMEs with a wide variety of variants and lean teams, FASTCUBE consistently reduces integration and programming effort. This is how automation can be used today: produce instead of program – without any special knowledge.

One platform. Many possibilities.

A clear focus: productivity.

- Cloud-based offline programming (SaaS) for manufacturing

- Modular OLP functions for different manufacturing tasks

- Hybrid architecture: cloud + existing IT + on-premises integration

- Connection to existing engineering and manufacturing systems

- Seamless integration of planning, engineering, and manufacturing data

As a cloud platform, FASTCUBE significantly lowers the barriers to entry for offline programming. The solution is available worldwide, flexible to use with customizable pricing models, and requires no high initial investment. This makes modern OLP accessible even to SMEs, for whom traditional offline programming has been too complex or too costly up to now.

Classic OLP reimagined—as a cloud platform

FASTCUBE is more than just a single application—it is an open, scalable, and future-proof platform. Its hybrid architecture adapts flexibly to existing IT strategies and can be seamlessly integrated into existing systems. The modular architecture makes it possible to gradually expand FASTCUBE with additional applications and functions. This creates digital continuity along the entire value chain. FASTCUBE acts as the digital backbone of manufacturing – not as an isolated island solution.

Classic OLP

- On-premises

- High initial costs

- For experts

- Not suitable for the shop floor

FASTCUBE

- Cloud & hybrid

- Modular & configurable

- For non-specialists

- Consistent digital thread between planning, engineering, and manufacturing

The FASTCUBE as a platform

FASTCUBE is not a standalone solution, but a modular platform. Each application addresses a specific production problem – ready for use today, expandable tomorrow.

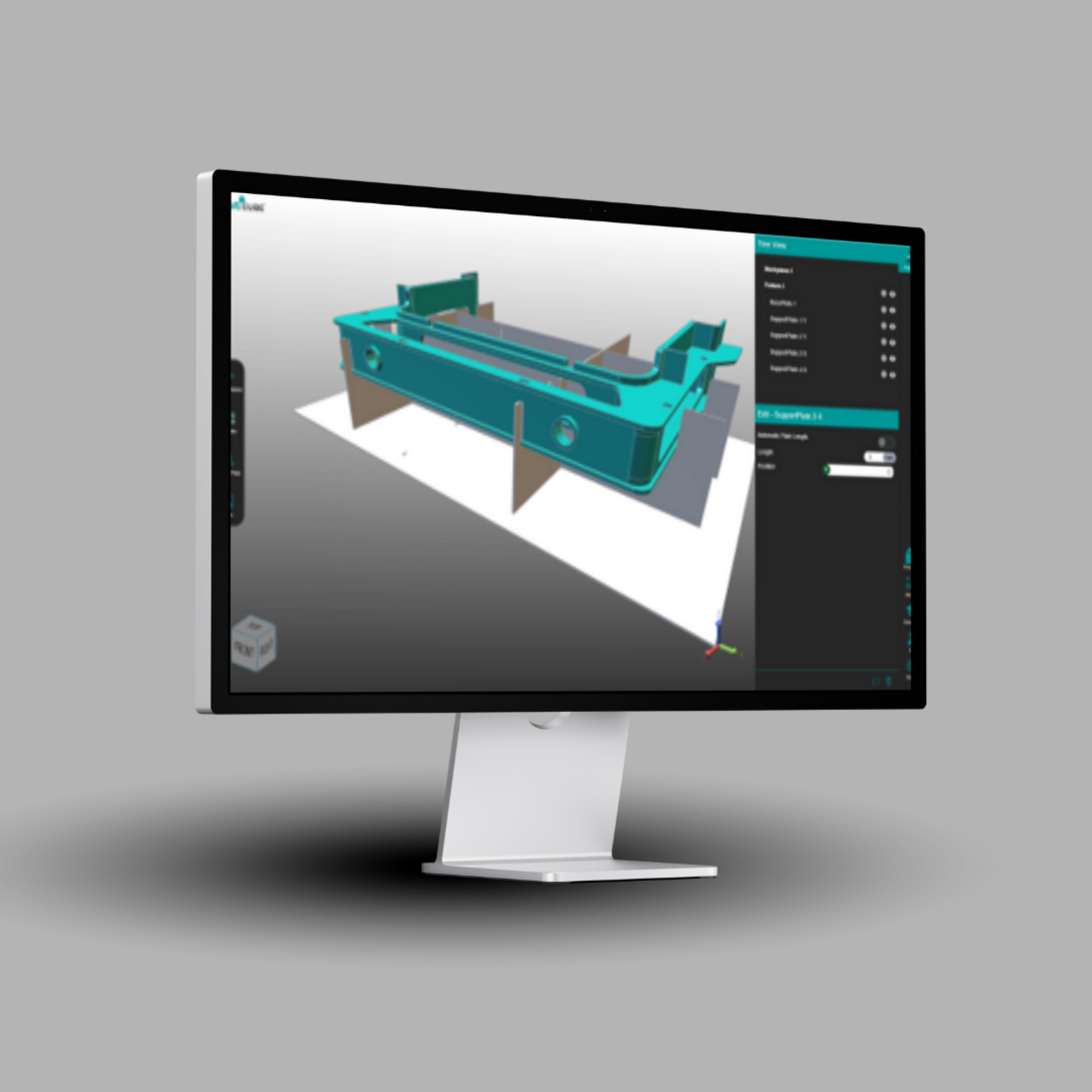

FASTCUBE Fixture Builder

Design fixtures – don't spend weeks constructing them

Automated fixture creation for welding and assembly processes with a high degree of variability.

In many manufacturing environments, fixture construction becomes a bottleneck: manual design processes, dependence on engineering resources, and long lead times for small batch sizes significantly slow down production. Frequent product changes also drive up costs and make flexible planning difficult.

This is where the FASTCUBE Fixture Builder comes in. With a consistent, automated workflow, it significantly reduces design effort and shortens design time by up to 75% – for a faster, more economical, and more flexible start to production.

- Automated creation of sheet metal fixtures

- Digital manual adjustment before export

- DXF export for immediate laser cutting

- Modular assembly concept

- Robot programmers work independently of engineering

FASTCUBE Shopfloor Assistant

Make changes where they arise: directly on the machine

Real-time program adjustments without downtime – safe, intuitive, efficient.

Program changes are part of everyday life in manufacturing – but they often cause production downtime, delays, and additional costs. Adjustments must be coordinated by the CAM office or made manually on the machine, which increases the risk of errors and collisions. This is where the FASTCUBE Shopfloor Assistant comes in. It bridges the gap between offline programming and actual production and creates the basis for safe, flexible adjustments directly on the shop floor – without downtime and without unnecessary complexity.

- Real-time program changes on the machine

- No production interruptions

- Intelligent collision avoidance

- Intuitive interface without in-depth programming knowledge

- Seamless integration into existing CAM workflows

Start today. Scale tomorrow.

FASTCUBE is the basis for pragmatic automation: productively deployable today, flexibly expandable tomorrow, and future-proof in the long term. The platform combines the depth of classic offline programming with the flexibility of a cloud solution—making OLP suitable for everyday industrial use for the first time.

The FASTCUBE Fixture Builder demonstrates how OLP expertise works without CAD dependency. As a modular, cloud-based application, it makes offline programming usable even for non-specialists and solves specific tasks in fixture construction quickly and efficiently.

Building on this, FASTCUBE brings offline programming to where it is needed: the shop floor. With the FASTCUBE Shop Floor Assistant, 3D simulation, program corrections, and collision checking are possible directly on the machine – without downtime and without the complexity of classic OLP systems.

The result is a platform that solves specific production problems, can be expanded step by step, and grows with the requirements of modern manufacturing.

Fetzer Contact me now